I love companies that make me think, “Why didn’t I think of that?” These are almost never pure technology plays because the technology is already there. It’s merely waiting for a clever company with a clever idea to make profitable use of it.

The technology-in-waiting here is 3D printing (also known as “additive manufacturing”). ActivArmor is not making any extraordinary demands of 3D printing technology. It’s not asking it to make houses… artificial organs… or wagyu beef. It’s simply asking for hard plastic casts.

But these hard plastic casts are better than traditional plaster casts in every way imaginable. They are…

- Available on demand

- Custom designed and fitted

- Waterproof

- Hygienic

- Comfortable

- Washable

- Adjustable

- Lightweight

- Breathable

- Durable

- Lockable (or not)

- Sanitizable

- Latex free

- Hypoallergenic.

One of ActivArmor’s casts being 3D printed

That’s not all. Physicians can choose whether the cast should be loose or tightly fitted. Doctors can order them in locked or removable form. Even when locked, it’s easy for the doctor to remove them during the healing process for examination or at the end of the healing process.

Patients easily 3D-map their injured limb through ActivArmor’s app on an iPhone. Within three to four days, ActivArmor delivers the cast to them (or their doctor) for fitting. The cast is tailored to their exact fit. It’s super comfortable and versatile. Patients can shower or swim with them and easily put them on or remove them (if unlocked).

ActivArmor originally manufactured these casts in a central location and delivered them to clinics within three to four days of the request. In a move to make scaling easier while improving the customer experience, ActivArmor will be providing its 3D printing hardware and software directly to clinics. As soon as the first quarter of next year, patients at these clinics will have to wait mere minutes to receive their casts.

The Vision: A Printer in Every Clinic

It’s another smart move by ActivArmor. But, of course, that’s only if the clinics are sufficiently incentivized to pay for ActivArmor’s 3D printers and software. So ActivArmor is making sure that clinics will have bigger margins with 3D printed casts than with traditional casts.

Let’s do some quick math. Clinics will pay a one-time fee of $15,000 for the 3D printer and training. They’ll also pay $1,500 every month to access ActivArmor’s automatic design software. With the subscription, they get 20 free designs per month. They pay $75 extra for each additional design. Clinics will also spend about $15 in plastic material per cast. That comes to $90 per cast — much cheaper than the $160 or so traditional casts cost.

And, remember, ActivArmor offers a far superior cast.

There’s not much reason for clinics to turn this down. But doctors and the medical community are a hidebound lot who tend to resist change. That’s true even when that change benefits them and their patients greatly.

I’m not concerned, though. ActivArmor is holding some strong cards as it kicks off its on-site printing marketing campaign.

ActivArmor is currently contracted with 40 hospitals and clinics. They’ve been sending ActivArmor scans to make casts for several years and are very happy with the results. ActivArmor says every single one of them has expressed interest in its on-site 3D printing option. ActivArmor will begin its campaign with these clinics. And it fully expects to convert most, if not all, of them to its new model. Several new clinics have already told ActivArmor’s dynamic founder and CEO, Diana Hall, that they’re also on board with in-clinic fabrication when it becomes available.

It’ll get harder when ActivArmor reaches out to clinics that are less familiar with what it does. But by that time, Diana should be able to point to a few dozen very happy clinics making more money from their casts than ever before. So clinics will be highly incentivized. They need to make only 40 casts before reaching breakeven on their initial $15,000 investment.

That’s nothing. Money talks. And doctors are no exception.

ActivArmor will reach self-sustainability once it converts its first 40 clinics. If all goes according to plan, that should happen by the third quarter of next year. By 2025, it expects to bring in revenue of $3 million to $5 million. From there, it has the potential to go several orders of magnitude higher in the second half of the decade.

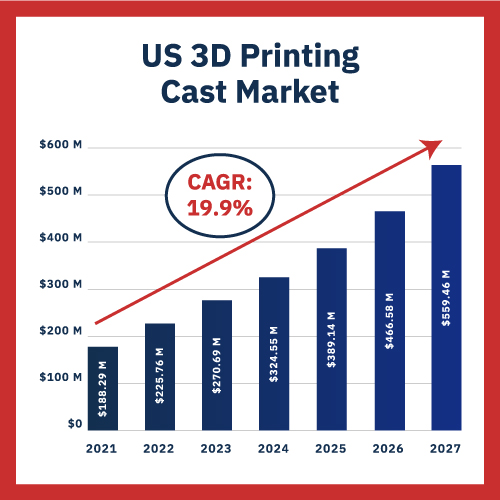

3D Printing Cast Market Set for Explosive Growth

And ActivArmor doesn’t have to be the market leader to do so. At $188 million, the 3D printing cast market isn’t huge, but it’s gearing up for explosive growth. Growing at a 19.9% yearly clip, it’s projected to hit $560 million by 2027. That’s good news for ActivArmor.

The timing couldn’t be better. Companies that establish their products now need only ride the market to grow rapidly. The future looks awfully promising for ActivArmor.

A League of Its Own

ActivArmor has competitors, but they don’t pose much of a threat. CastPrint has only one clinic in the U.S. Xkelet offers software and support for 3D printing. It’s active in London and Spain but has not made its way across the Atlantic. There are other companies trying to develop the requisite combination of hardware and software. But so far, they haven’t been able to commercialize any of their technology.

ActivArmor is leading the pack right now. Other companies could catch up eventually. But it won’t be easy for them. The technology took Diana eight years to perfect. ActivArmor is now making the final tweaks to its custom design software. The 3D product mapping… the right sizing and customized fit… the impressive functionality… the range of options doctors can now choose from… the clinically tested product portfolio of casts and splints for everyone from infants to the elderly… all of these took time, effort, determination and, importantly, a resilient founder.

Diana ran the company on her own for the last eight years with barely any salary. As a businesswoman, she convinced 40 clinics to use her company’s services. As an engineer, she handled the drop in business during the height of the COVID-19 crisis by developing and selling 3D printed transparent masks. Her leadership skills and resourcefulness are beyond question.

And they’re about to pay off. There are risks, of course. Doctors may decide to stick with their “tried and true” ancient plaster casts. But on what grounds? A 3D printer is too much of a hassle to operate? I’m fishing here. ActivArmor is sure to appeal to those doctors who care about better patient outcomes in addition to those who care about increasing profits. The vast majority of orthopedists fall into one or both of those camps.

Here’s how I see the next few years playing out. In the first couple of years, clinics will be asked to play offense — grabbing patients by offering a better 3D printed product than the doctor using plaster casts down the street. As 3D printed casts grow rapidly and become more widely adopted, clinics will be forced to play defense. As 2027 draws closer, clinics will not be able to ignore the many benefits of ActivArmor’s casts — their practicality, versatility, comfort, affordability, range of designs, customizable fit and long-lasting material.

And that’s when ActivArmor’s high upside should be realized. A more far-fetched scenario is these comfort-fitted casts holding little or no appeal to doctors and patients. The much greater risk for you is not investing in the new era of 3D printed casts. ActivArmor makes your choice easy.

Deal Details

Startup: ActivArmor

Security type: Common shares

Valuation: $21.9 million

Price per share: $1.70

Offering Maximum: $5 Million

Minimum investment: $170

Where to invest: StartEngine

Deadline: November 4, 2022

How to Invest

ActivArmor is raising up to $5 million on StartEngine. If you don’t already have a StartEngine account, you can sign up for one here. Once you’re logged in to StartEngine, go to the ActivArmor deal page. Be sure to review the deal page and offering circular thoroughly before making an investment.

Then click the green “Invest Now” button. Enter the amount you want to invest, starting as low as $170, and proceed through the required steps. Be sure your investment is confirmed, then you’re good to go.

Risks

This opportunity, like all early-stage investments, is risky. Early stage investments often fail. ActivArmor might need to raise another round of funding in a year or two, if not sooner. If it executes well, this shouldn’t be a problem. But that’s a risk worth considering when investing in early stage companies.

The investment you’re making is NOT liquid. Expect to hold your position for five to 10 years. An earlier exit is always possible but should not be expected.

All that said, I believe ActivArmor offers an attractive risk-reward ratio.